6 top tips to help you get the most out of stainless steel screws

When strength, corrosion resistance, and durability are essential, stainless steel screws are the go-to choice for both professionals and DIY enthusiasts. They perform exceptionally well in outdoor, marine, and high-moisture environments, offering a rust-free, long-lasting finish. But even the best screws can only perform at their peak when used correctly. Whether you’re working on decking, cladding, joinery, or metalwork, a few smart techniques can make all the difference.

Here are six top tips from MyTradeSupplies to help you get the most out of your stainless steel screws.

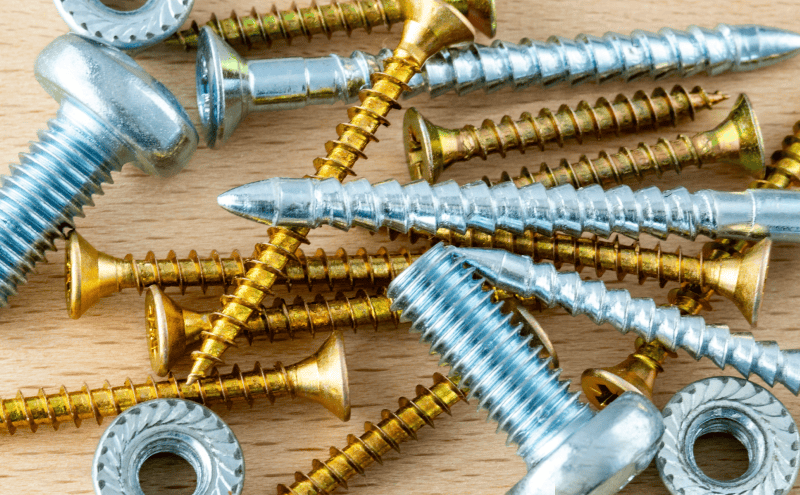

1. Choose the Right Grade for the Job

The two most common grades of stainless steel screws are A2 (304) and A4 (316).

- A2 is ideal for general outdoor applications such as garden furniture, fencing, and timber construction.

- A4 is the better choice for harsh or coastal environments. Its molybdenum content enhances resistance to pitting and corrosion caused by salt or chemicals.

Choosing the correct grade from the outset ensures longer screw life, prevents corrosion-related failures, and maintains the aesthetic of your finished project.

2. Store Screws in a Dry, Covered Space

Even though stainless steel is corrosion-resistant, improper storage can still lead to staining or damage.

- Keep your screws in a dry, well-ventilated area, ideally in their original packaging or sealed containers.

- Avoid leaving them exposed to moisture, damp workshops, or outdoor conditions.

Prolonged contact with water, other metals, or airborne contaminants like iron filings can cause surface contamination or tea staining. Proper storage is one of the simplest ways to keep your fixings in pristine condition until you need them.

3. Always Use the Correct Driver Bit

It might sound basic, but using the right driver bit makes a big difference. Stainless steel screws are softer than carbon steel and can strip easily if the bit doesn’t fit properly.

- Whether your screws have a Phillips, Pozi, Torx, or hex head, make sure the bit matches exactly and is in good condition.

- Using the correct bit provides better grip and control, reduces the risk of cam-out, and ensures a neater, more professional finish.

4. Control Drill Speed and Pressure

Driving stainless steel screws requires a measured, steady approach. Excessive speed or pressure generates friction, which can overheat the metal and cause galling—when threads seize mid-drive.

- Use a moderate drill speed with steady, even pressure.

- Pre-drill pilot holes when working with hardwoods or metal to reduce strain and prevent snapping.

This ensures cleaner, more accurate installations and preserves the integrity of both the screw and the material.

5. Use Lubricant to Prevent Galling

When driving stainless steel screws into other stainless components, galling can be a real headache—threads can weld together, making removal nearly impossible.

- Apply a small amount of wax-based lubricant or anti-seize compound to reduce friction and allow smoother installation.

- This is especially valuable for high-torque or repetitive applications, helping preserve both your screws and your workflow.

Always ensure your chosen lubricant is suitable for your materials and won’t stain visible surfaces.

6. Avoid Galvanic Corrosion

Galvanic corrosion occurs when dissimilar metals come into contact in the presence of moisture. For example, stainless steel screws in contact with aluminium, zinc, or mild steel can cause the less noble metal to corrode faster.

- Use insulating washers or plastic grommets.

- Apply a non-conductive barrier between metals.

This small precaution dramatically extends the lifespan of both components, especially in marine or outdoor settings where exposure to salt and moisture is unavoidable.

Need Expert Advice?

At MyTradeSupplies, we stock a comprehensive range of stainless steel screws, fixings, and fasteners—all at unbeatable prices. Whether you’re tackling a large construction project or a small home improvement job, we’ve got the perfect fixings for every application.

If you’d like expert advice on choosing the right screw for your project, our friendly team is always happy to help. Call us on 01254 4917744 – and we’ll make sure you get exactly what you need for a job well done.